Applications

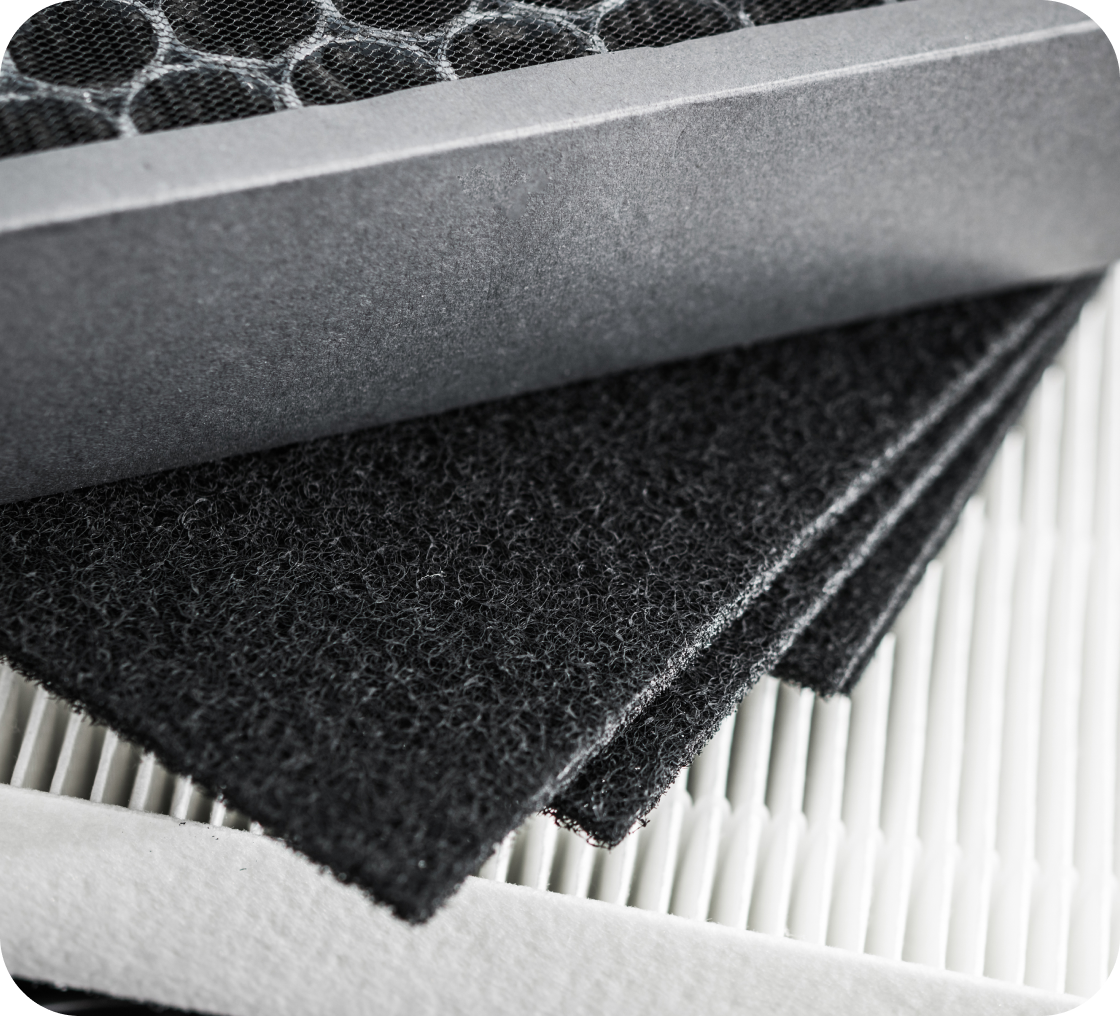

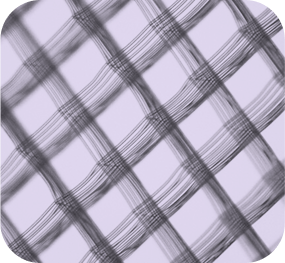

Membranes for the Filtration Sector

Microfiltration has become increasingly popular as a pretreatment method for purifying air and water, with medical, biological, and industrial applications. It’s also used for removing hormones and microorganisms from water surfaces and wastewater through porous membranes with pore sizes ranging from 0.1 to 10 microns.

However, contaminants often clog and foul these membranes, significantly reducing the efficiency of the process.

Pretreatment refers to the stage that precedes actual filtration.

By removing larger contaminant particles with a pre-filter, the main filter unit can operate more efficiently and for longer periods before requiring cleaning or replacement, leading to cost savings and less waste.

R&D Service

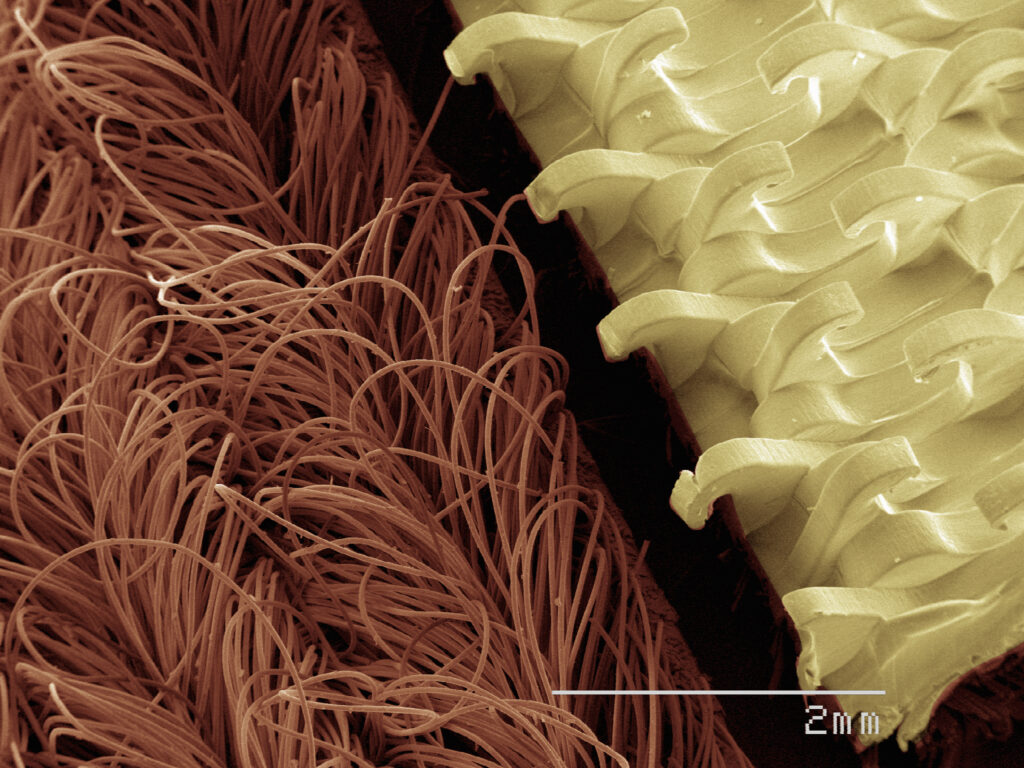

Traditional fibers vs. nanofibers

The core element in filtration membranes is polymers of various types. Traditional polymer membranes can be manufactured using different techniques, but they often suffer from high fouling rates and low flow capacity.

This is typically due to an asymmetric pore distribution and a surface populated by tiny pores that easily get clogged, while the low permeability is due to poor porosity overall.

Nanofiber membranes have gained significant traction over the last decade due to their unique physical and mechanical properties: a large surface-to-volume ratio (providing an ample filtration area in a minimal volume) and nanometric pores, which make them ideal for a wide range of applications, particularly in filtration.

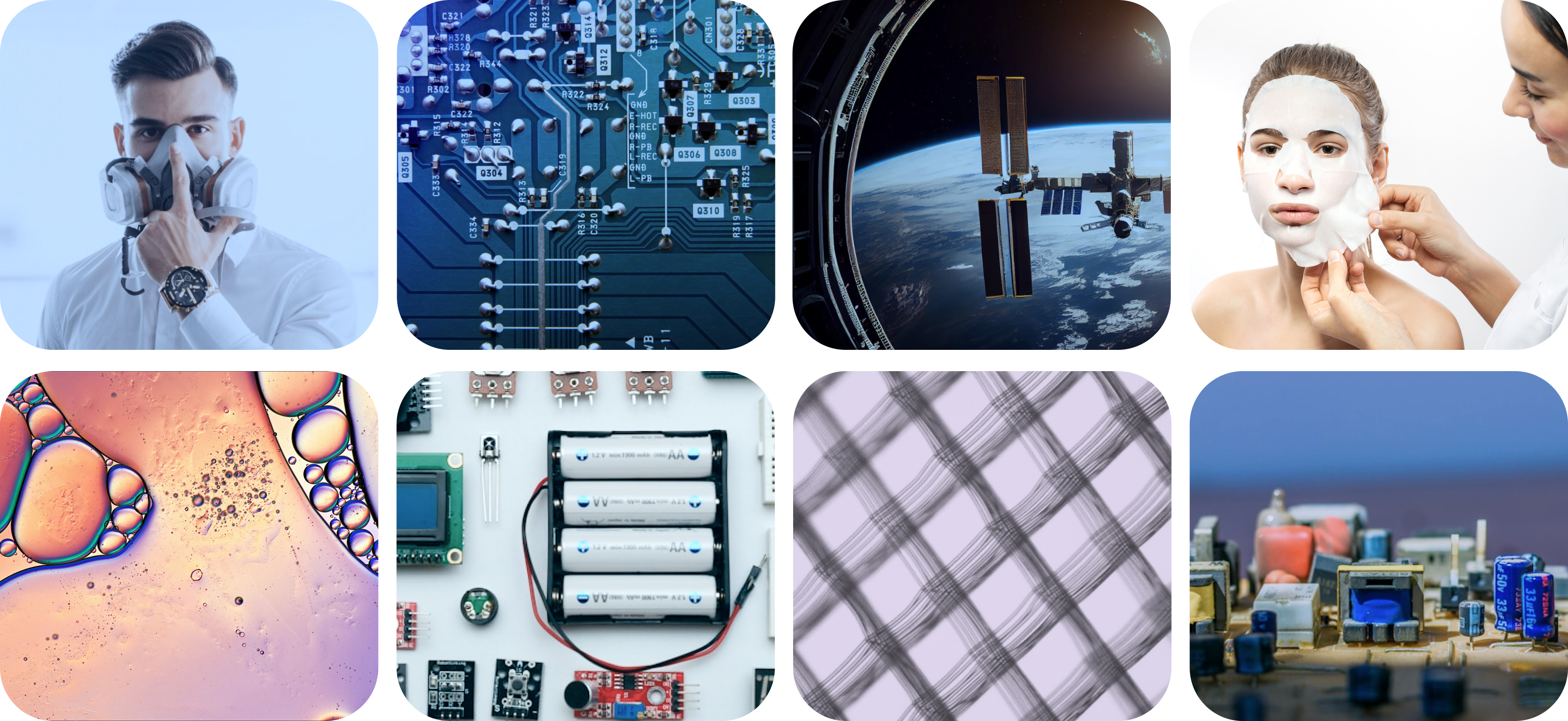

Applications

Air and water filtration

Nanofibers produced via needleless electrospinning enable highly efficient air and water filtration. Their interconnected pores, adjustable porosity, nanometric diameter, and high surface-to-volume ratio enhance permeability and separation efficiency.

They are used in oil-water separation, virus and bacteria removal, heavy metal absorption, wastewater treatment, and membrane distillation, offering lightweight, scalable, and high-performance solutions.

Electronics

Needleless electrospun nanofibers transform electronics by providing high surface area, flexibility, and lightweight properties.

They enable conductive nanofibrous interconnects, flexible electronics, and high-density 3D architectures for miniaturized devices. Insulating nanofibers improve dielectric performance, signal stability, and component density. Applications include wearables, flexible displays, smart sensors, and compact high-performance semiconductor devices.

Energy Production and Storage

Nanofibers made via needleless electrospinning are key in energy systems. As electrodes in supercapacitors, lithium-ion batteries, and fuel cells, they boost conductivity, reaction area, and lifespan.

Combined with advanced materials like graphene, they increase storage capacity, charging speed, and efficiency. Nanofibers are also used in gas separation membranes, solar energy storage, and electronics for heat dissipation, offering scalable, lightweight, and sustainable solutions.

Tissue Engineering

Needleless electrospun nanofibers mimic extracellular matrix structures for tissue engineering. They create uniform, 3D, biodegradable scaffolds that support cell adhesion, proliferation, and differentiation. Incorporating biomolecules during production enables multifunctional scaffolds for enhanced regeneration.

Applications include cardiac patches, neural repair, and other tissue-specific scaffolds, providing precise, biocompatible, and highly customizable solutions for regenerative medicine.

Cosmetics

Nanofibers produced via needleless electrospinning enable controlled delivery of cosmetic actives. Used in masks, patches, or sprays, they improve penetration and release of moisturizers, anti-aging, or soothing agents. Incorporating vitamins, botanicals, or other actives allows personalized skincare.

Lightweight, porous, and biodegradable, these nanofibers create effective, comfortable, and environmentally responsible cosmetic products adaptable to diverse skin needs.

Drug Delivery

Needleless electrospun nanofibers are ideal for controlled drug delivery. Drugs can be embedded during production for sustained or pulsatile release, improving efficacy and reducing side effects.

They suit transdermal patches, biodegradable implants, and oral capsules. Combining natural and synthetic polymers allows targeting specific sites, such as tumors or infection zones. Scalable and contamination-free, they provide versatile, high-performance pharmaceutical solutions.

Sensors

Nanofibers produced via needleless electrospinning are essential for high-sensitivity sensors. Their high surface area and functionalization with nanoparticles, semiconductors, or conductive polymers enable precise detection of gases, humidity, temperature, or biomarkers.

Flexible and lightweight, they integrate into wearable or portable devices. They also enhance dielectric properties in chip insulators, minimizing signal loss and ensuring stable, reliable performance at large scale.

Aerospace

Needleless electrospun nanofibers support aerospace materials with high strength, energy dissipation, and light weight. They are used in structural composites, protective coatings, and ventilation filters, improving safety and efficiency. Applications also include thermal insulation and fire-resistant materials to protect spacecraft during launch and re-entry. Scalable production ensures uniform fibers, meeting the precision, reliability, and performance standards of the aerospace industry.