Discover electrospinning, the process that creates nanometric-diameter fibers, known as nanofibers, from polymer solutions.

Nanofibers are fibers with diameters on the nanometer scale. At Invenio, we produce them by processing polymer solutions through electrospinning. Here’s how their size compares to more common fibers:

1 m = 100 cm = 1,000 mm

1 mm = 1,000 µm = 1,000,000 nm

Wool fiber diameter = 30–120 µm

Silk fiber diameter = 20 µm

Microfiber diameter = 2–5 µm

Nanofiber diameter = 0.05–1 µm

Polymers are the essential ingredient for producing fine and ultra-fine fibers. Nanofibers can be created from either molten polymers (those that melt at high temperatures) or from polymers in solution.

Typically, nanofibers are not used as single threads, but as randomly entangled mats with a nonwoven structure. Geometrically, nanofibers have a very high surface-to-volume ratio and much higher specific surface area (side-area per weight) than microfibers or traditional fibers. They also form highly porous membranes with extremely small pores.

With Neatess®, our breakthrough nanofiber membrane, Invenio introduces a new frontier in air filtration: efficient, sustainable, and high-performing.

We chose electrospinning because it allows for the creation of nanometric-diameter fibers from polymer solutions.

Fiber formation occurs as the solvent evaporates while the polymer solution passes through a high-voltage electric field.

In-depth details

The first patent for this method dates back to 1902, developed by J.F. Cooley and W.J. Morton, who designed a system to disperse fluids using strong electric fields.

Electrospinning enables the creation of nanofibers from both natural and synthetic polymers.

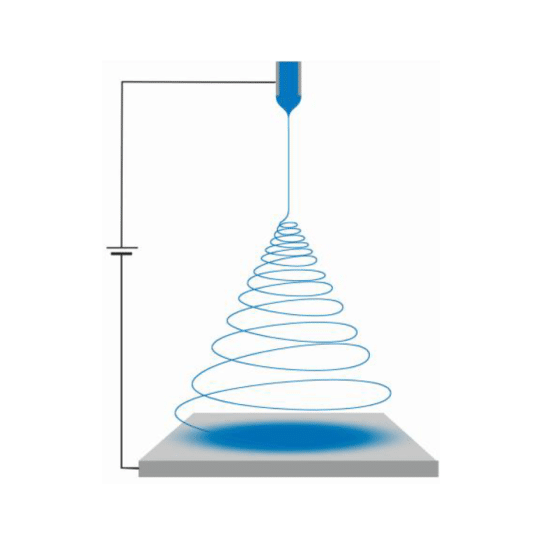

The solution containing the polymer is loaded into a syringe with a needle (called a spinneret) and is pushed through it using a pump. A high-voltage electric field is applied between the spinneret and the collector, where the nanofibers are deposited.

As the solution exits the needle, the electric field deforms the droplet into a “Taylor cone.” At the tip of the cone, a jet emerges and stretches into a long, thin fiber.

Free charges within the solution interact with the electric field, and the potential difference between the spinneret and collector causes the jet to form.

These jets travel from the spinneret to the collector while the solvent evaporates. By the time the fibers reach the collector, the solvent has dissipated, leaving behind dry, solid fibers.

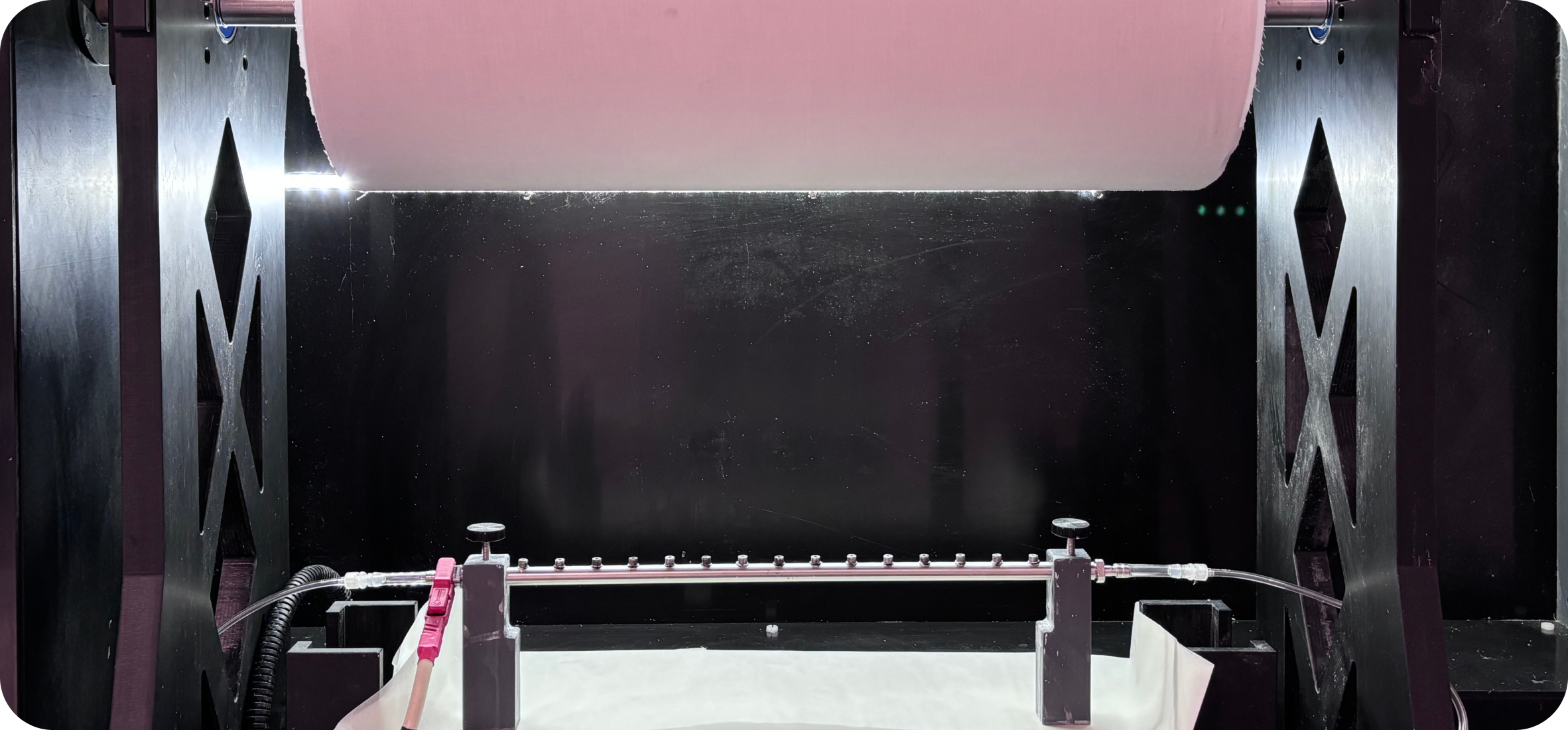

Invenio uses needleless electrospinning.

Originally developed in the early 1970s, this method has been refined by numerous research teams exploring various spinneret shapes. Needleless electrospinning systems continue to evolve today.

In these systems, polymer solution jets form directly on the free surface of the liquid. Multiple jets emerge simultaneously from the spinneret.

The onset of fiber formation and the resulting fiber morphology are strongly influenced by the intensity profile of the electric field, which depends on both the applied voltage and the shape of the needleless spinneret.

Nanofibers produced via needleless electrospinning can be used in a wide range of applications, including tissue engineering, drug delivery, wound treatment, sensors, energy generation and storage, protection and safety, air and liquid filtration. For these reasons this is the preferred technique for industrial-scale nanofiber production, thanks to the ability to provide high productivity, versatile fibers suited to multiple sectors, and an efficient, scalable process.

Via Emilio Ciocca 24/26 – Codogno (LO), Italy

P.IVA 11306580967

© 2024 Qode Interactive, All Rights Reserved